As one of the leading suppliers in vacuum brazing technology, we join a wide variety of materials – primarily copper and stainless steel – but also other materials. The produced material joints are vacuum-tight, mechanically highly resilient, oxidation-free, absolutely clean and free of any solder residues. The capillary action ensures an optimum soldered seam – even in hard-to-reach places. This creates strong compounds that are characterised by very high strength and corrosion resistance.

In our specially developed and electrically heated vacuum furnaces, we use the vacuum to prevent the oxidation that starts during heating. In addition, by using gases such as nitrogen or argon, we can create special ambient atmospheres that offer many different advantages.

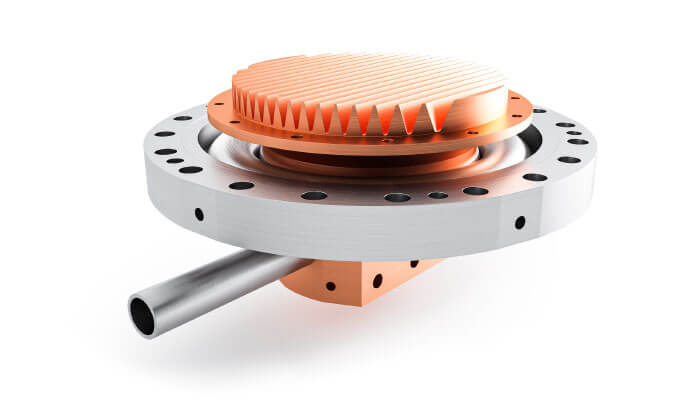

Application: : Cooling unit for CSR storage ring

Operating conditions: -271 to +350 °C

Special feature: Leakage rate <1x10E-9 mbar x l/s

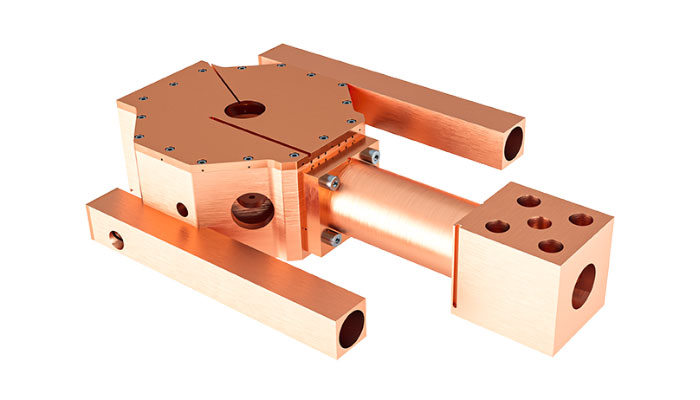

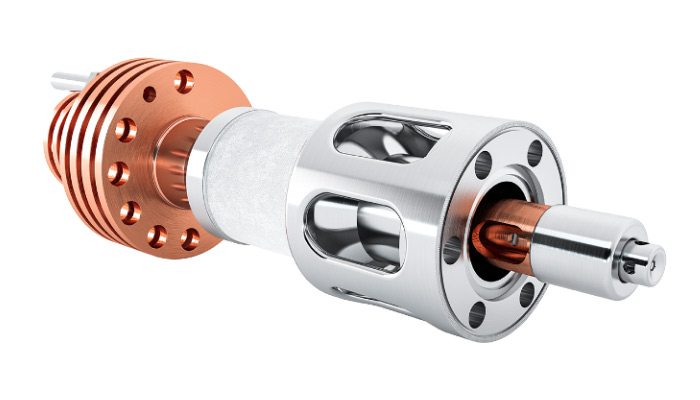

Application: Ion sources

Special feature: Over 30 individual parts joined in one step

Function: Electromagnetic radiation shielding

Operating conditions: Temperatures up to 80°K (-190 °C)

Special feature: UHV-compatible purity, tolerance up to 0.01 mm

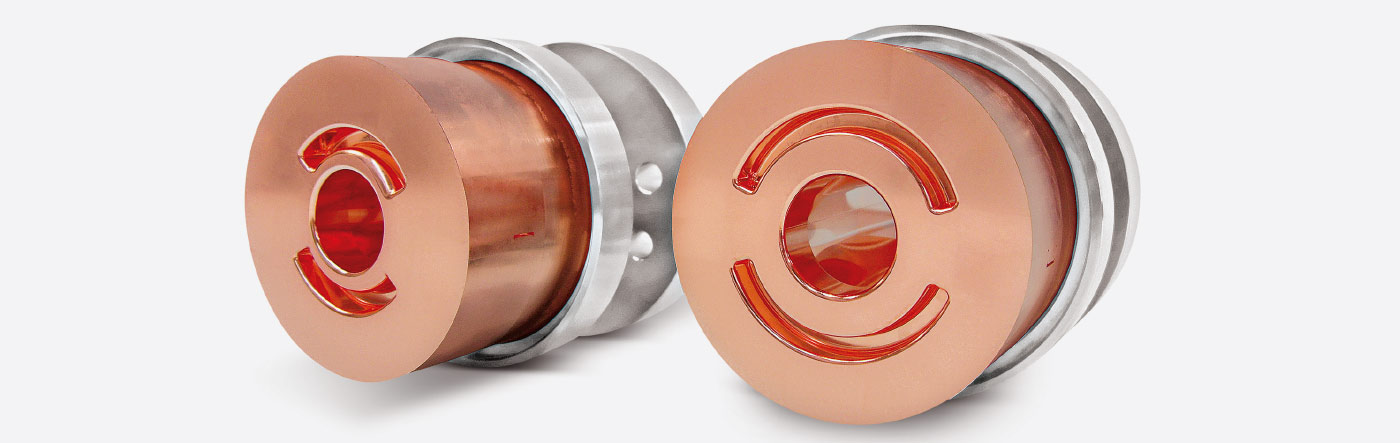

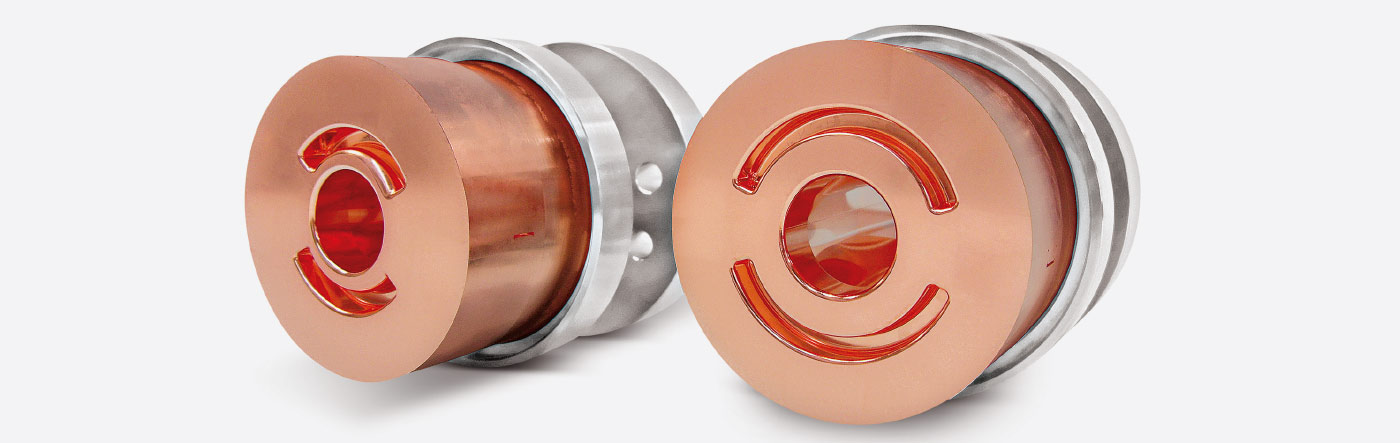

Application: Ion source

Function: Collecting/removing free electrons

Special feature: Leak-tight up to 1x10E-10 mbar x l/s, cylindricity <0.05mm, UHV-compatible purity

REUTER TECHNOLOGIE GmbH

Röntgenstraße 1 - D-63755 Alzenau