A number of the most exciting scientific projects of our time require a precision that seemed impossible until just a few years ago. Both in mechanical machining and in joining technology, the requirements today go to the limits of what is technically feasible.

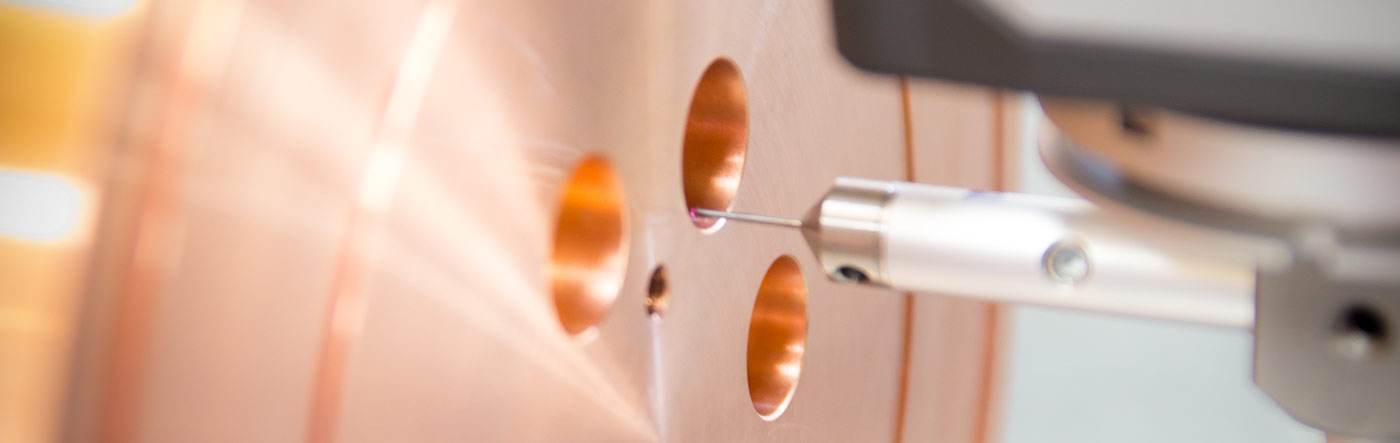

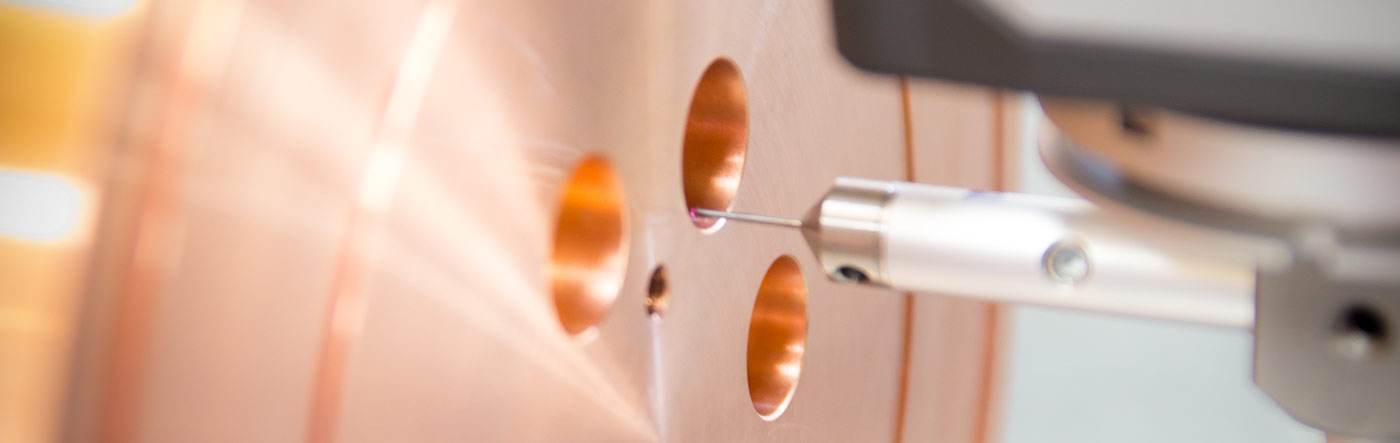

We have adjusted to this. With our technology, we are able to achieve shape tolerances for free-form surfaces of 0.02 mm in combination with an average roughness depth of 0.1 µm (in some cases up to 25 nm) directly on the machine.

During production and also afterwards, the dimensions produced are checked and documented using state-of-the-art measuring and testing equipment.

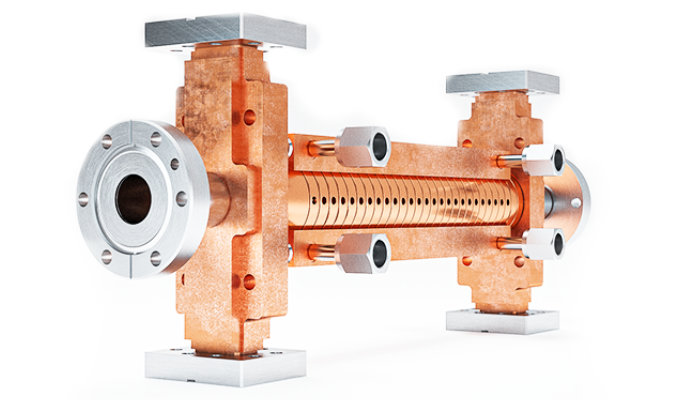

We machine complex components and assemblies in copper and stainless steel on our modern CNC machining centres, including machines from Hermle, Grob and DMG. Frequently, 5 axes or the creation of open-shape surfaces are also used. Through our membership in established networks, we continue to secure access to the latest technologies and insights in precision engineering.

REUTER TECHNOLOGIE GmbH

Röntgenstraße 1 - D-63755 Alzenau