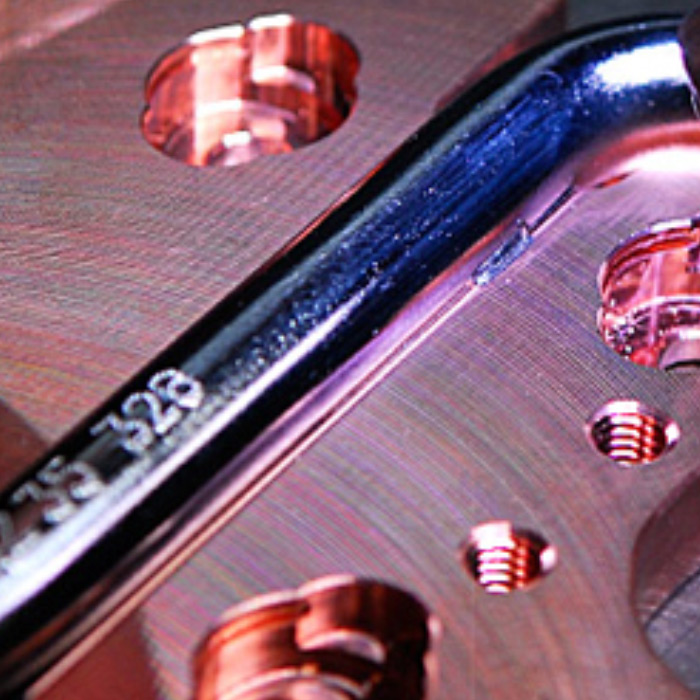

REUTER TECHNOLOGIE relies on both hand-guided and CNC-controlled laser welding systems. In this way, the most suitable seam geometries can be implemented.

Laser welding allows materials to be joined vacuum-tight at the surface. The distortion of the components remains very low. Other important advantages are:

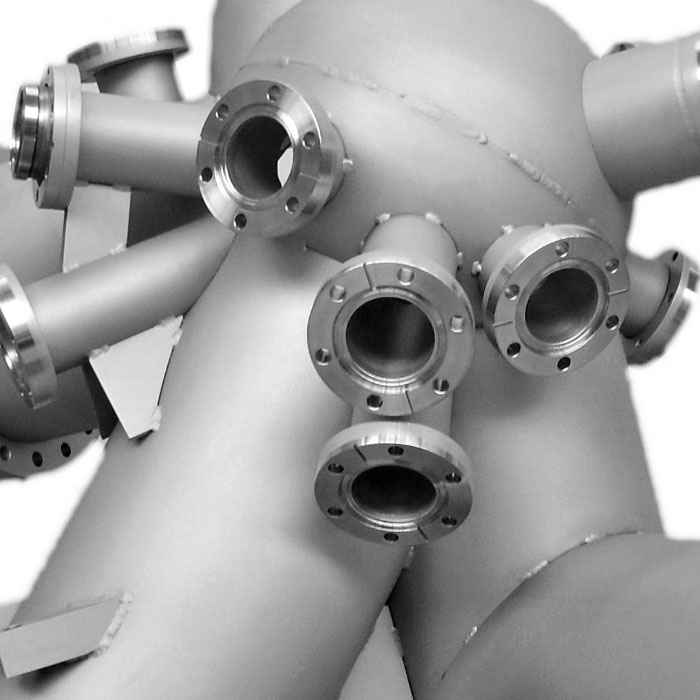

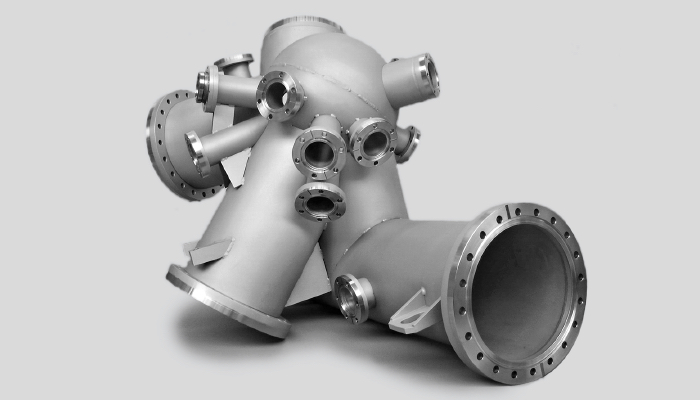

TIG welding can be used to join almost all weldable materials such as high-alloy steels, aluminium and non-ferrous metals. Our strength in this field: high and ultra-high vacuum welding.

TIG welding is generally characterised by high process reliability and very good weld seam quality. Therefore, this process can be used universally to create permanent bonds between metals.

We have many years of experience in this field and can offer very demanding high- and ultra-high-vacuum welding as a special strength.

Stainless steel vacuum chamber with CF connections for laboratory and experimental purposes. Manually TIG welded.

Stainless steel vacuum chamber for electrochemical treatment of samples. Manually welded vacuum-tight using the TIG process.

REUTER TECHNOLOGIE GmbH

Röntgenstraße 1 - D-63755 Alzenau