Heat treatment in a vacuum

For perfect material properties & surfaces

Every application places special demands on the material. Often these properties can only be realised by heat treatments such as annealing, hardening and tempering. REUTER TECHNOLOGIE offers ovens of various sizes for this purpose. Depending on the method, we can reach temperatures of up to 1600 °C. We protect oxygen-sensitive materials with an atmosphere of nitrogen, argon or hydrogen.

We remove impurities from the surface of your components through heat treatment processes in a vacuum. Our ovens are electronically controlled and monitored. This means that different processes can also be combined with each other. For this purpose, we offer suitable additional processes such as packaging in N2-flooded containers. Ask us, we will be happy to advise you!

Heat treatment processes:

- Hydrogen degassing annealing

- Stress-relief annealing

- Demagnetisation annealing (reduction of permeability)

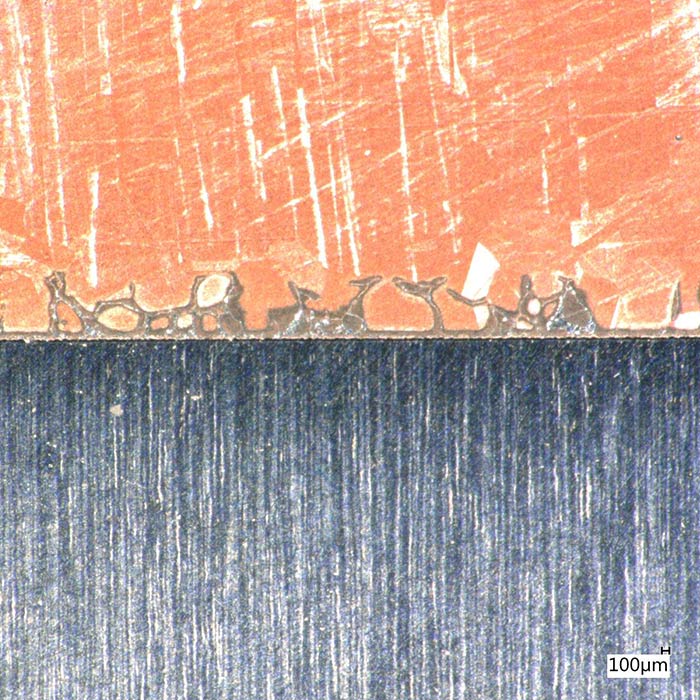

- Diffusion / solution annealing

- Recrystallisation annealing

- Soft annealing

- Normal annealing

- Hardening and tempering of stainless steel

- Hardening and tempering of high-alloy steel

- Vacuum annealing